New Publication in the HIPOBAT project

Title

Lithium plating in commercial lithium-ion cells: An extensive study combining electrical methods with post-mortem analysis

Link

https://www.sciencedirect.com/science/article/pii/S2352152X25024193?via%3Dihub

Summary

This study correlates established electrical detection methods with results of a post-mortem investigation. Commercial cells were therefore charged under a variety of operating conditions, including variations in temperature, current, cooling, clamping pressure and state-of-charge. Indicators of Li plating were analyzed using electrical stripping and voltage relaxation measurements. The post-mortem analysis included the digital image processing of over 5000 flatbed scans of anode electrode surfaces.

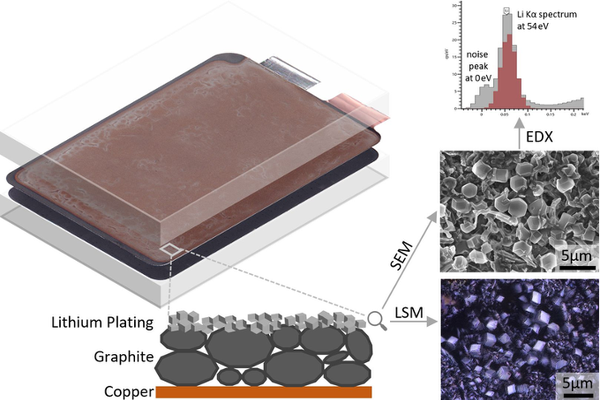

To analyze the Li plating morphology and validate that the observed macroscopic structures are lithium plating, laser-scanning and scanning electron microscopy measurements combined with energy dispersive X-ray (EDX) analysis were performed. The use of a windowless EDX detector enabled the measurement of Li K𝛼 X-rays at 54 eV, thereby confirming the presence of lithium metal in the grown structures. The structural analysis of the surface deposits revealed, for the first time in a commercial cell, a novel polyhedral Li plating morphology. These results contribute to the field of Li plating detection, as it is essential to understand the plating process and detect metallic lithium at an early stage in order to optimize battery lifetime and increase safety for the target application.

Interview with the lead author and researcher in the HIPOBAT project, Heinrich Ditler, RWTH Aachen:

Q: Lithium plating is a well-known degradation phenomenon in Lithium-ion batteries with graphite anodes during fast-charging at low temperatures. Could you briefly explain how your work contributes to the detection of lithium plating and how it is different from previous studies?

A: Our study combines electrical detection methods with large-scale post-mortem digital image analysis on commercial high-power cells. We not only correlate electrical Li plating differential voltage analysis (DVA) indicators with direct visual evidence of lithium plating, but also introduce an automated computer vision approach for quantifying and mapping Li plating across thousands of electrode flatbed scans. We also systematically demonstrated via post-mortem methods that re-intercalation of plated lithium into graphite can occur within less than one hour after charging, an effect that had not been directly visualized before. Finally, for the first time, we discovered a new polyhedral lithium plating morphology in commercial cells, which was also confirmed by windowless SEM-EDX. Therefore, this publication offers both improved quantification methods and novel insights compared to earlier works.

Q: You have used high-power commercial cells as device under test. Will it be possible to extend the methodology you developed to other electrochemical systems, lab demonstrator cells, such as Na-ion batteries or solid-state batteries?

A: Yes, we are already actively working on adapting our methods to other electrochemical systems. Our current research already shows a high transferability of the methodology to sodium-ion cells. We also aim to explore and expand the methodology for solid-state batteries in future research within the HiPoBat project.

Q: Have you planned a follow-up work based on the results of this study? If so, can you give us a teaser? Is there the potential to develop this methodology further?

A: Absolutely! We plan to further investigate different lithium/sodium plating morphologies under various conditions and to further automate our image analysis pipeline for larger datasets and other cell formats. We're also looking into non-invasive operando methods like ultrasound or X-ray tomography to complement our current approach.